The most Affordable Software in its Class!

|

Introduction to Cabinet Pro |

||||||

|

| General Features of Cabinet Pro | ||||||||||||||||||||||||||||||||

|

| Custom Cabinets | ||

|

| Support of Several Languages, and regional forms of English | ||

|

| Design and Graphics Features | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Some features of the Floorplan Designer (two examples of video tutorials that are part of our free Learning Curriculum) | |

|

|

|

|

Multiple Views |

Automatic Placement of Finished Ends |

| Cutlists and Door Reports | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| Bidding and Invoicing | ||||||||||||||||||||||||||||||||

|

| Grain Options and Grain Matching | ||||||||||||||||

|

| Panel Optimization: Nesting and Point-To-Point | ||||||||||||||||||||||||||||||||||||||||||||||

|

| Automatic Inventory Control | ||||||||||||||||||||||||||||||

|

| Security System (for companies with multiple users) | ||||||||||||||||

|

| Networks (for companies with multiple users) | ||||||||||||||||||||||

|

| Custom Programming (for companies with unique requirements) | ||

|

| Hinge Location Reports for Doors and Adjoining Sides |

| In the CNC Version, these holes are drilled automatically. In the Standard Version, this report is given to aid the cabinet maker in drilling his/her hinge plate holes and holes on the door itself. |

|

|

| The CNC Edition | ||||||||

|

The most Affordable Software in its Class!

|

Introduction to Cabinet Pro CNC |

||||||

|

| Advantages of Handling Design, Cutlists, Bidding, Optimization, and CNC in One Program | |||||||||||||||||||||||

|

Most Cabinet Design Software require the saving of DXF files to be used by other CAD/CAM programs to generate CNC code. Cabinet Pro CNC generates its own code without the need for 3rd party software. See the letter below from one customer who understands the importance of this feature. This fact in itself has a number of benefits:

|

|

||||||||||||||||||||||

|

A Letter from a long time customer... |

|

|

July, 2014

Dear Frank and Eliana Just taking some time to express appreciation for your program. I have had the program now for 9 years, purchased at the Vegas show at about the time you were integrating the CNC capabilities. What got me, of course, was the price, which was 1/2 to 1/3 of your competitors. I had software at the time that I had used for several years and was about to add a CNC "module" to it. Your complete CNC product cost was about 1/2 of just the "module" and was fully integrated without having to deal with a completely different program to run the router.

The ability to customize and build cabinets in the program is

virtually unlimited. Curves and odd shaped cabinets are easily

executed and sent to the router. I have had other programs

presented to me over the years, and your program is

by far the biggest bang

for the buck. On-going improvement of the program and the

versatility it allows lets me use it for any type of cabinet.

I've even used it to design caskets and cut them on the router! Closets with KD fittings are easily set

up with a few clicks.

I guess the best thing about the program is that the customer

becomes part of the 'team' at Cabinet Pro. Features can be added

for any individual shop's need and as such becomes a resource for

other shops using the program to tweek their operation as well.

The videos answer most questions and if not, Frank or Eliana are

there to help on the phone or email. Sometimes customers uncover a

bug or other problem with the program and Frank will go right to

work on it. Sometimes I find I have simply not checked the right

box. It takes some time to realize all the features of the program

but is worth the effort and learning curve.

Thanks again.

Larry Lee

Pearl River Cabinet Company

Carriere, Ms

|

|

| The CNC Operation, as processed by Cabinet Pro | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

When Cabinet Pro produces a cutlist, the

panels are simultaneously sent to the Panel Optimizer which produces the G-Code

Code behind the scenes to operate your CNC router. The Cuts that are made

automatically, depending upon your setup, are as follows:

Do you manufacture face frame or frameless cabinets?

Do you make modular or highly custom cabinets? If so, then imagine a new

way of operating your cabinet shop with Cabinet Pro CNC Software:

Load your CNC router with panel stock and watch the parts be automatically machined and

cut out with perfection and efficiency. |

| Cabinet Pro CNC General Features | |||||||||||||||

|

|||||||||||||||

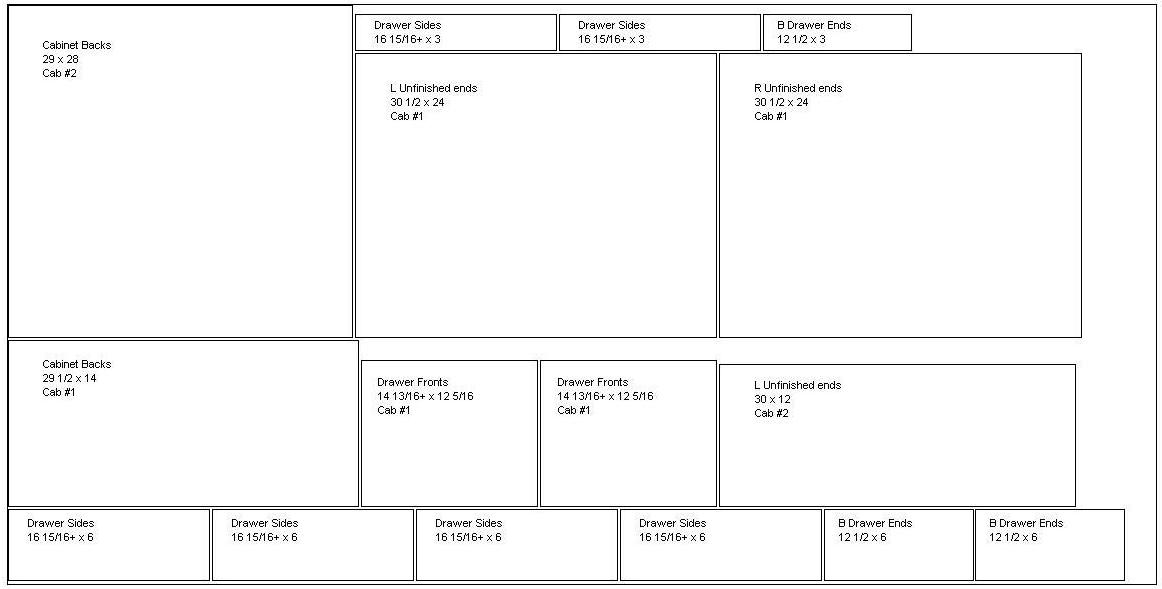

| Panel Optimization and Nesting | ||||||||||||||||||||||||||||||||||||||||||||

|

| Labels, Bar Codes, and Labels Carved into each Part (click a picture to enlarge) | |||||||||||

At the right is shown the same sheet of optimized parts. The top picture shows the sheet as it appears on Cabinet Pro's optimizer on the CNC or non-CNC versions of Cabinet Pro or Door Pro. This may be printed out in addition to individual part labels shown below. For those who want the cabinet number, job number, room number, edge banded sides, and part name to be etched directly onto the part by the CNC router, Cabinet Pro allows this option as well. The user has the option of defining on which parts labels should be carved, and which parts should be left blank. Below are show labels that may be printed via your printer. These labels are available for both the CNC version and the Standard, non-CNC, version of Cabinet Pro. |

|

||||||||||

|

A sheet with labeled parts as is shown on Cabinet Pro's Panel Optimizer. |

|||||||||||

|

|

|

||||||||||

|

Regular Cabinet or Part labels may be printed directly or from Word |

The same sheet as is shown on a CNC simulator with labels carved into each part. |

||||||||||

| MDF Doors and Door Processing | ||||||||||||||||||

|

| Cabinet Pro's Smart CNC Rules: Automatic Machining | |||||||||||||||||||||||||||||||||||||||

Cabinet Pro's Smart CNC Rules make

automatic machining a reality. These rules associate specific machining

operations to various parts based a number of rules that may be set up by the

user. Some of these rules are as follows:

|

|||||||||||||||||||||||||||||||||||||||

| Blind Dado Construction | |||||||||||||||||||||||||||||||||||||

Blind dado

construction, or mortise & tenon construction, is not only one of

the strongest forms of cabinet construction but it is also highly

aesthetic and makes assembly very quick. Blind Dado

construction is but one type of construction of many

supported by Cabinet Pro CNC.

Alternatively,

|

|||||||||||||||||||||||||||||||||||||

| Supported CNC Routers within Cabinet Pro | ||||||||||

|

Supported CNC Languages:

Most CNC routers read an industry standard

language called "G-Code". Although most routers supported by Cabinet Pro CNC accept G-Code instructions,

we also write to machines requiring other languages as well, such as Woodwop,

BiesseWorks, and Wincut. You may customize the g-code output, since Cabinet Pro CNC allows the post

processor to be user-defined. Cabinet Pro supports all CNC routers that use Woodwop, Biesseworks, Wincut, Xylog, or any variation of g-code. Because Cabinet Pro's post processor is user-defined, the CNC code can be greatly modified, if necessary. So if different commands are needed, or if commands need to be ordered in a different sequence than is part of the already existing post processors listed below, this can be done very easily within Cabinet Pro (or Door Pro). We will work with someone of your choosing, who is familiar with the g-code necessary to run your machine, and within a very short time will have your g-code output matching the specific requirements of your CNC router.

Please Note:

If your CNC router

requires code that is unique or slightly different from the posts

listed above, we may need to modify an already

existing Post Processor for your specific machine. This is a

relatively simple task and

will be done

at no additional charge, as long as you are willing to help test the

modifications, and the changes

are not extensive. |

||||||||||

Click here for a comparison study of Cabinet Pro